A personal opinion

Basically, on the Suzuki oil injection system the outside lines lube the outer mains, the Middle oil lines oil the piston skirt & oil from both of them mixes with the gas. The inner mains are oiled by the transmission oil.

To go pre-mix the “Slingers” or as the parts book says – “PLATE, oil guide” have to be removed from the outer bearings. The slingers direct the collected oil through the crank pin for additional big end lubrication.

To prepare for pre-mix the bearings have to be removed and the slingers replaced with the same sized thrust washer. Make sure the spacers ( washers ) are the same thickness and that their diameter is not too large, as to cover the bearing cage.

But, why do it? The wealth of opinion, for anything less than Grand Prix racing, is to keep the pump and standard oil lines. For the road, keeping the pump is a no-brainer. For most people’s racing, keeping the pump is a safe option. The pump etc does no weigh much nor rob significant performance.

Even racing the bighters we keep the pump, especially for long distance endurance races. The only time we ran without was with a modified crank when we ran full on race watercooled motors.

The oil injection system is safe reliable and makes these motors strong and durable, even when ported and raced hard!

In summary: it is simple, modify the crank if you remove pump, or keep the pump and still have reliable and confidence in your motor.

Our TR500 Mk11 doesn’t have an oil pump but it comes from the factory ready to run pre-mix.

I raced T500 modified to TR specs for years with oil pump set to one third on at all times and some 1:50 pre mix combined, totally reliable.

This debate arises every few monrths. Suzuki advised retain oil pump when they 1st raced the 500. Do what you like but don’t remove oil pump without modifying crank as described previouly.

Muzza

Bernie Kerr in NZ is very expereinced with racing 250 and 500 Suzuki twins, this his view on pre-mix…

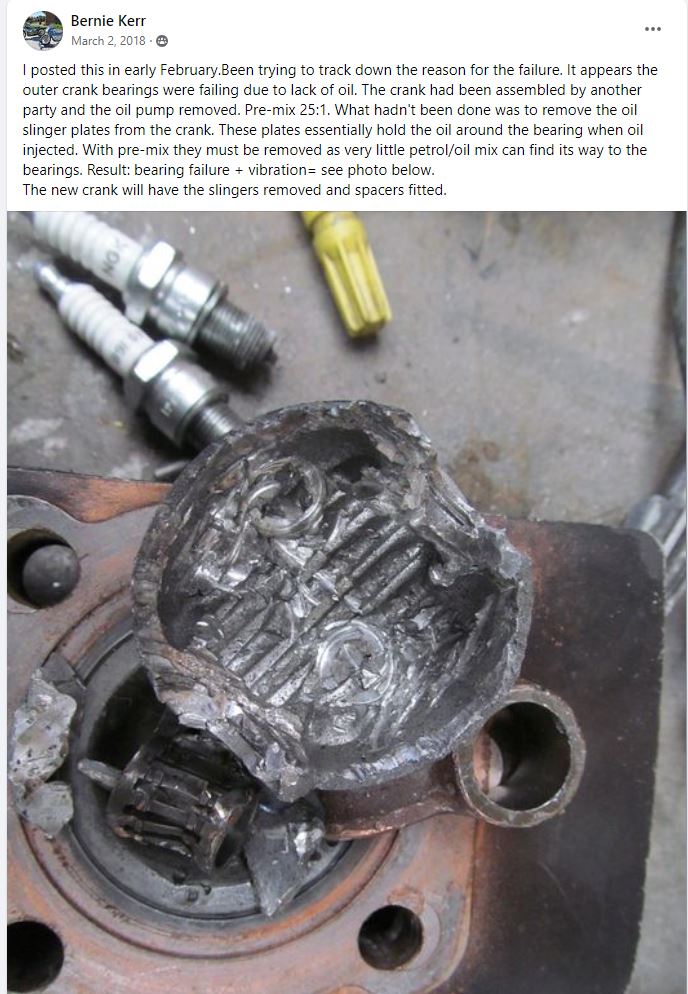

Bernie Kerr races the Suzuki twins, below is a sad example of what can go wrong if assembled incorrectly with pre-mix…..

Aldosuzuki adds to the discussion:

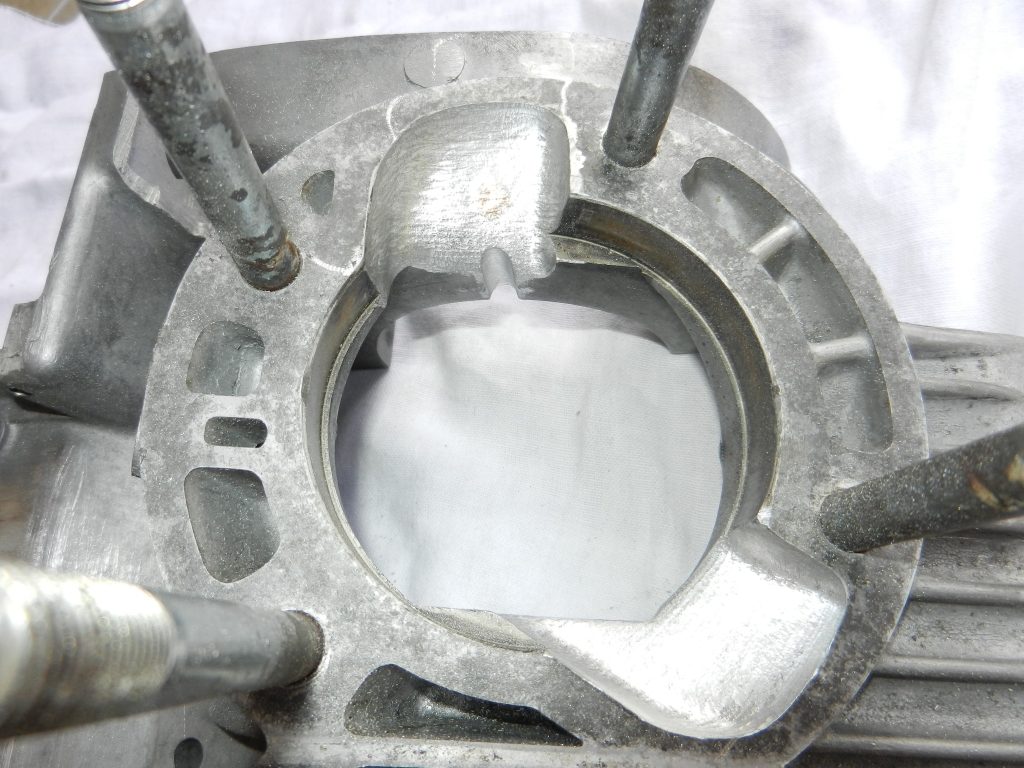

The mixing pump and associated oil lines can be safely removed. The crankcase must be machined to allow lubrication of the side bearings as per photo below. Without separate lubrication, a 3% mixture must be used. I use this system on a Suzuki TR250 and TR500 with no problems.

Nic Montagu adds his solution:

An oil feed hole needs to be drilled from the transfer port to meet/align with bearing oil hole. Crank does not need to be machined but oil slingers to be removed and replaced with same width washer of smaller diameter so that bearings are exposed to oil mist.