by Glen Morgan from New Zealand |

The stock T500 head is actually a good design for its purpose, but it is a compromise

between production costs and performance. The stock head is a shallow section of a

hemisphere on top of a low perpendicular wall.

Its advantages are that it has a relatively low surface area for heat absorbtion and it

has little in the way of areas where unburnt mixture can lurk, because the previously

mentioned walls raise the roof of the combustion chamber well clear of the piston. The low

surface area means that there is less area to absorb heat from combustion and this helps

to keep the head temperature down. This in turn helps to control detonation. Accordingly,

a reasonably high compression ratio can be run to the benefit of performance. ( But not

the kind of compression ratio that most people associate with a racing motor, because this

design has definite limitations at higher compression ratios.)

The elimination of dead spots of unburnt mixture means that fuel economy is better because

more of the charge is doing work.

[Emission control is also better because unburnt fuel is not being ejected into the

environment with the exhaust gases, and this may have been one of the prime motivations

for using this design. Even in those days, there were rumblings in the important

Californian market.] If you consider that an ineffective squish head can be worse in

all respects than the stock T500 combustion chamber, this simple design begins to make

sense. Of course, for racing most people want more power than the stock head can deliver

reliably. It follows that most of us would like to have a more appropriate head design, so

we need to look at the possibilities that a squish combustion chamber offers. [ I'm

assuming that the reader is new to this sort of thing. If I have over simplified things, I

apologise in advance to those who are familiar with the topic.]

First up, the ignition of the fuel/air mixture does not cause a sudden explosion which

drives the piston downward. Indeed that condition is called "detonation" and it

is exactly what we don't want. Normally, a rapid but controlled burning of the mixture

heats the air (mostly nitrogen) in the cylinder. This expands the air and drives the

piston downward. There is a physical law ( Boyle's Law ) which says that compressing

gas raises its temperature. If you compress the air/fuel mixture in the cylinder enough it

will reach a temperature where it will ignite. There is a sudden engine-stressing rise in

pressure and heat is absorbed into the piston and cylinder head faster than it can be got

rid of through the cooling system. This detonation can be initiated at lower

pressures by things like hot spots, hot end gases and active radicals. Instead of the

flame front travelling out rapidly (but progressively) from the spark plug, ignition can

occur in other places. This causes all sorts of complex thermal and chemical goings on.

I'm deliberately avoiding discussion of the role active radicals, mixture stratification,

shock waves, colliding flame fronts and pre-ignition.

[Apparently, chaos theory has gone a long way toward providing a model for what's going

on, but fractals are a bit beyond me, so I don't have anything really meaty to offer the

keen engine freak]. For our purposes, discussion of hot end gases will get us

to where we want to go. (Even though there is a hell of a lot more to it!). As you

probably already know, out on the edge of a combustion chamber there may be unscavenged

areas where hot gases can initiate detonation. A long time ago, a British researcher,

called Riccardo, discovered that inferior fuels could be used at higher compression ratios

if the deck of the head in side valve, four stroke engines was brought down close to the

piston and the mixture was squeezed into a compact combustion chamber over the valves.

There are two positive effects to this. Firstly, the mixture where the head and the piston

are in close proximity loses its heat so rapidly that it cannot ignite, so hot end gases

can't cause detonation. The down side of this is that, unless the thin layer of mixture is

very thin, most of this unburnt mixture goes out the exhaust without doing any work, as

previously mentioned. The second effect of "squishing" the mixture like this is

that it shoots out of the "squish area" at quite a high velocity into the

compact combustion space and the resultant turbulence mixes the mixture up quite

thoroughly. This helps to give even and controllable combustion. Two stroke

designers adapted these findings and put a concentric squish band around a ( usually)

hemispherical combustion chamber with the spark plug in the middle.

At this point, they had three preconditions for good

combustion control: squish to control peripheral temperatures and squeeze end gases out

into the main combustion area - turbulence for a homogeneous mixture - and a combustion

chamber shape and spark plug location which allowed the flame front to travel almost

evenly in all directions.

[Once again I'm skirting around complex topics. Briefly, in answer to the question,

"why not have a spherical chamber then?" a sphere with the ignition point in the

centre looks perfect but having half the combustion chamber in the piston crown increases

the surface area for absorbtion of heat into the piston and causes all sorts of problems.

Sometimes, shapes other than variations on a hemisphere are used because they can reduce

the mechanical stresses on components. I have a Kawasaki engine with a truncated, conical

combustion chamber, apparently in the interests of bearing life ]

A further advantage of a squish area is that while the mixture under a squish band of

appropriate clearance cannot ignite, the droplets of fuel in the mixture can evaporate

when they contact the relatively warm surfaces of the head and piston in the squish area.

This change of state causes heat to be absorbed (latent heat if evaporation) and this

cools the head and the piston. In general, quite a significant part of a two stroke's

cooling can come from having a slightly over-rich mixture to aid cooling. This is

particularly so in air cooled engines.

The problem from a manufacturers point of view is that, to be effective, the squish band

needs to be quite accurately machined, with respect to piston to head clearance.

Variations in manufacturing tolerances or wear in service could lead to the piston hitting

the head. The result is that manufactures err on the side of safety to the point where the

occasional engine has a squish band which is of little use. An over large squish clearance

can lead to 10-15% of the mixture doing no useful work as it disappears, unburnt, out the

exhaust port. Worse still, an excessive squish clearance can harbour hot end gasses which

can cause detonation.

The Shape of Things to Come

Now we are in a position to look at how we might modify the T500's heads to get the best

we can out of what we have. It has been suggested to me that a squish band can be created

in a T500 head by machining the face of the head down until the piston and the outer rim

of the combustion chamber are close enough to form a squish band.

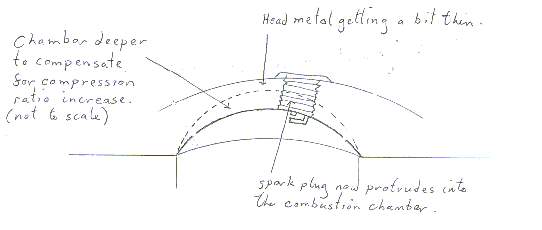

This suggestion does have some fish hooks in it. If the T500 combustion chamber were a

simple dome shape, this approach would probably provide a reasonably effective and simple

solution. But the T500 has, as previously mentioned, a wall which continues into the head

at about bore diameter before the shallow dome starts.

If you machine the head to barrel mating surface down as far as you can without destroying

the head's structural integrity, you will just get to the edge of the domed section. At

this point, the proximity of the combustion chamber surface and the piston may give you

the worst possible scenario: clearance which is too large to squish effectively and

masking of the area by the domed contour which characterises the shape of the T500 piston.

This masking effect could cause hot end gases to be unscavenged, and initiate detonation.

Added to this, the compression ratio will be way too high because so much volume has been

taken out of the combustion chamber. A further complication is that removing so much metal

will reduce the beam strength of the head and make head warping and gasket sealing

problems a real possibility. To get back to a reasonable compression ratio, the combustion

chamber would have to be re-worked to a deeper hemisphere inside the area which is being

regarded as a squish band. To do this, the thickness of the head would have to be reduced.

This in turn would mean that the spark plug threads would protrude into the combustion

chamber.

There are a few reasons why this situation is not optimal: exposed plug threads become

corroded and carboned up. When plugs are changed, the thread in the head will probably be

damaged as the corroded, carboned up plugs are wound back through them. Direct exposure to

combustion will cause the plug to heat up and this will be made worse by less threaded

surface being in the head to conduct heat away. Further, the less "meat" there

is in the head, the more prone the head itself will be to heat up. All in all, this means

of creating a squish head in this way is fraught with problems.

( I guess that one could have the plug boss built up with weld, or use a thick copper

washer to raise the plug out of the chamber, but I couldn't recommend the last solution as

good engineering.) Okay, I'm not going to say that machining the head

down to create a squish band won't work. After all, I haven't tried it! But I'm more

than a little uneasy about it as a way to go about getting performance with reliability.

If I started with a clean slate and was designing a squish head for my own T500, I'd

design a combustion chamber to fit my needs. I don't have a close ratio box and one of the

circuits I race on regularly is very tight, rather like a big kart track. I want low

maintenance and a decent amount of power with reliability, but I do need a bit of mumbo

too, because the other circuit I ride at is a long one by any standards and I don't want

to be going so slow that I fall asleep in the main straight. If you can lay

your hands on a typical enduro single of the same period as the T500, have a look at the

combustion chamber. That's the way I'd go - wide squish band and a deepish hemispherical

combustion chamber. This would suit mid range power and a peak at about 7500 revs. I'd be

looking for a compression ratio at around 12.5 to one, even a little less.

Right, so why don't I just fill a T500 head in with weld and machine out the kind of

deepish chamber I'm looking for? The answer is that I'd run into a problem we've seen

before. The T500 head isn't thick enough to easily get a deep chamber into it. True, I

could get the face of the head built up with weld to give the extra depth, but that much

welding and machining could really cost. I could make some patterns and get a pair of

heads sand cast. It would also be possible to make patterns out of existing heads by

building them up with panel filler to increase the thickness where the head meets the

barrel.

[ Making two stroke heads is actually not such a tall order but I have a back ground

(ancient history now) in foundry work, so it's easy for me to say that. There are a few

complicating factors in pattern making, like taper and shrinkage, that need to be taken

into account too. ]

But the reality is that getting heads cast is not a real option for most people, so weld

filling and re-machining is probably the main option. We've already seen that the

thickness of the standard head limits our combustion chamber design a bit, so what can we

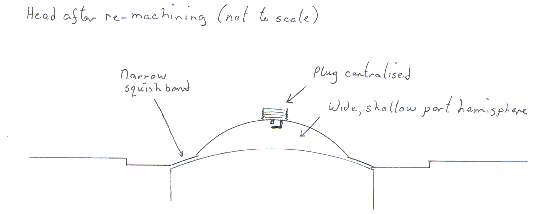

do? First of all we need to look at what variation in chamber shape and squish band width

might do. Things have moved on a bit since I first got interested in two stroke tuning.

Once 50% bore area was regarded as about right for a squish band. (see diagram 2.) Squish

was just squish - the more the better. But it turns out that combustion chamber shape and

squish characteristics can be optimised for different engine and power characteristics.

Too much squish can be less than optimal under certain conditions [There are computer

programmes which can give information about optimal combustion chamber shapes to produce

the appropriate amount of squish for certain performance parameters. Dr Gordon Blair has

published a book (very expensive) about the finer points of two stroke design and it comes

with programme discs. Also check out the MacDizzy two stroke site

(http://www.macdizzy.com/2stroke.htm) for all sorts of Two stroke design programmes.]

Basically, as I understand it, motors which are required to produce grunt at lower RPM use

higher squish velosities (like motocross and enduro engines) and road race type engines,

which rev higher, need lower squish velosities. This leads to enduro type engines with

wider squish bands and deeper hemisheres. At the other end of the scale there are road

race engines with narrower squish bands and wider, shallower hemispherical chambers. This

seems simple enough, but some MX engines for experts are getting toward the road race end

of the tuning spectrum, particularly the small capacity ones. Also, things like the angle

between the piston surface and the squish surface have an influence on squish velocity,

and even the radius where the squish area transitions into the hemispherical chamber has

an influence on things.

At this stage, you are probably thinking, "This guy is not making it easy."

Well, it's not as bad as it seems because, although the old bangers we ride are a bit like

a couple of 1970s enduro motors side by side, we also tend to use our engines further up

the rev range than even a full blown Mxer of that period. From this it follows that a bit

less squish (and a bit less compression for that matter) might actually be beneficial.

This, by the nature of the heads we are dealing with, is what we will wind up with if we

fill T500 heads with weld and form new combustion chambers in them.

You need a relatively shallow chamber because there is not enough "meat" in the head for a deep one. To get the volume necessary to avoid an excessively high compression ratio, the combustion chamber needs to be quite wide. Therefore, the squish band tends to wind up on the narrow side and the squish velocity will be lower.

So what have we got? Something that is probably not optimal, but if we set up the squish

clearance at a minimum of 40-45 thou and have the two surfaces parallel we should be ok.

(Assuming that the engine is in good condition. If those bottom end bearings are stuffed,

then you could wind up bouncing the pistons off the heads.)

Note that the squish band will work better if the surfaces diverge slightly - around 2 degrees should do.

[WARNING******* If you rebuild a motor, swap heads from

one motor to another or buy some squish heads from someone, you will have no comeback if

the pistons collide with the heads or the squish clearance is too great. Variations in

manufacture do occur. Rods can vary in lenth and pistons can vary in deck height above the

pin. YOU MUST CHECK EVERY TIME YOU DO SOMETHING TO YOUR MOTOR********]

If we open the chamber out enough to give about a 12.5 to 1 compression ratio with an

exhaust system that works properly, we will have enough squish band width left to do the

job and the whole plot should have more mumbo and less inclination to detonation.

Note that I am using the traditional compression ratio calculation, not the one measured

from the top of the exhaust port - see Bell's book on two stroke tuning.

The picture is of a pair of heads of my own: -

But being a glutton for punishment, I have off-set the combustion chambers away from the

exhaust port side of the cylinders. This is to shift the heat away from the hottest side

and even out the temperature across the piston crown. In theory, this allows a higher

compression ratio, because the hot spot adjacent to the exhaust port gets cooled by the

wider squish area. It also makes the piston less inclined to seize in this often critical

area. It can be kept simple by just keeping the chamber central. The plug should be moved

to the centre of the chamber to get even flame front travel. In any case, if the plug is

left in the standard position, it can enter the new chamber quite awkwardly. If you keep

the chamber central, you can fill-weld the plug and put in a new central one without

having to perform much fancy surgery to the fins.

Now for the disclaimer! To work properly, squish heads needs to be set up properly. Get A.

Graham Bell's book on tuning two strokes. It's very practical and easy to follow. I can

also recommend Eric Gorr's books and writings as a step up from Bell's book (which was

written a while ago now).

What I have written here is far from the last word on T500 heads. I am not brave enough to

say - "Here are the optimal dimensions. Do it like this." I don't know how your

particular engine is set up, and there could be a whole range of possibilities, depending

on what you have done.

For example:

| stock engine | leave the heads alone. |

| stock engine with mild chambers | centralise the spark plugs |

| stock engine with a small compression rise and mild exhaust chambers |

centralise plugs and retard ignition slightly |

| exhaust port mods, exhaust chambers and compression rise |

modify the head and retard the ignition |

This can go on and on as we get further up the tuning scale and optimal head design

becomes more critical. You may also be wondering what the hell retarding the ignition has

got to do with it! Buy a good tuning book! It is also possible to have a situation

where reducing the compression back to standard may be a good idea. Why? Well, an

effective exhaust chamber can stuff the mixture back into the cylinder at a pressure that

equates to damn near 7 psi of boost. My point is that everything is affected by something

else so buy a good tuning book!

While we are on the subject of things being affected by other things, we should have a

brief look at some of the wrinkles in fitting a squish head so that it works.

If the piston is nearly kissing the squish band at maximum RPM, there are tuners who would

regard this as optimal clearance. I've got a couple of esoteric reservations about that,

but the point is that, though too much clearance is not good, too little will wreck your

engine. Rods stretch under the stress of high RPM and things expand with heat. A minimum

cold static clearance between the squish band and the piston of 40-45 thousandths of an

inch (or the metric equivalent) is generally recommended for an engine of the size and

type of the T500.

This is for an engine in good condition. If it's got a lot of mileage up, more clearance

may be necessary. In the real world, engines wear out, (and in the real world some of us

go racing on what we can afford ). So give some thought to this!

There are things like plasticine, soft solder and specialised products that can be used to

measure this clearance. Again, a good tuning book will tell you about this. It may be

necessary to machine a bit off the tops of the barrels on a T500 to get the clearance

right. Do this with caution, because if you take too much off you can't simply put an

extra gasket or a plate under the barrel. Raising barrels like this changes all the port

timings on a T500.

Try to avoid this kind of scenario: you take too much off the top of the barrel, so you

but a plate under the barrel to get the right clearance. But this has changed your

transfer and exhaust port timing . You decide that an increase in transfer blow-down time

will probably be ok, and you can live with the extreme exhaust port timing if you make a

new set of exhaust chambers and buy a close gear cluster! However, when you grind out the

inlet port to restore the timing there, you run out of metal - aaagh!

Friend of mine many years ago bought a problem T500, which he told me was "hot"

but unreliable. It had a compression ratio that would have detonated alcohol and there was

evidence of the kind of nightmare outlined above. We replaced the heads and barrels with

stock ones and he discovered that "nearly as quick as a popular Triumph of the

period" didn't do justice to a good stock T500. The moral is obvious.

Have fun and email me (atmorgan@wave.co.nz) with anything you'd like to add from your own

experience. I'm happy to answer questions that don't extend me beyond my own experience,

and I'll try to point you in the direction of wiser heads if I can.

Glen Morgan

(Thanks Glenn for sharing your thoughts on this topic)